Egg Yolk and White Separator

Egg powder production line consists of: 1. Egg cleaning machine 2. Egg breaking(&separating) Machine 3. Egg liquid proce

Send your inquiryDESCRIPTION

Basic Info

| Trademark | GENYOND |

| Origin | China |

| Production Capacity | 2000-12000PCS |

Product Description

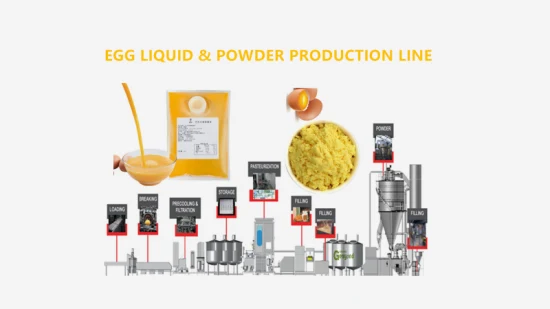

Egg powder production line consists of:

1. Egg cleaning machine

2. Egg breaking(&separating) Machine

3. Egg liquid processing machine: filtration ; sterilization

4. Drying machine for whole egg liquid / egg yolks / egg white

Eggs powder Production Line: is a whole automatic egg processing line with the following process:

Eggs Feeding→ Eggs Washing and Drying→ Eggs Candling→ Egg Breaking &Separating→ Eggs Filter & pasteurizer→drying machine

Egg breaking machine is used for breaking and separating eggs.

We mainly have three types for your choosing.

* Eggs Breaking Machine: is only used to break eggs.

* Eggs Breaking and Separating Machine: is used to break eggs and then separate egg yolk from egg-white automatically.

Technical Parameters of Egg breaking machine:

Model | Capacity | Wash&dry&candle part size/mm | Break&separate part size/mm | Each Filter part size/mm | Power /Voltage |

GYEB-3600 | 3600eggs/h | 2900*700*1400 | 2700*1100*1200 | 1500*1000*650 | 7.05KW/380V |

GYEB-8000 | 8000eggs/h | 3800*900*1400 | 2700*1100*1200 | 1500*1000*650 | 7.25KW/380V |

GYEB-10000 | 10000eggs/h | 3800*900*1400 | 3710*1200*1400 | 1500*1000*650 | 7.6KW/380V |

Egg liquid pasteurizer is applicable to heating,sterilization,heat preservation and cooling etc.t

* Control methods:semi-automatic control, full-automatic control(PLC control, touch screen display)

* Main accessories: material pump, balancing tank,hot water system, temperature controller and recorder,electric control sysem etc.

Technical Parameter of Egg liquid pasteurizer:

Model | GY-P1-01 | GY-P1-02 | GY-P1-05 | GY-P1-10 | |

Production capacity | t/h | 1 | 2 | 5 | 10 |

Heat exchanging area | m2 | 8 | 13 | 28 | 52 |

Temperature of material inlet | °C | 5 | 5 | 5 | 5 |

Temperature of material outlet | °C | 5 | 5 | 5 | 5 |

Sterilizing temperature | °C | 85-95 | 85-95 | 85-95 | 85-95 |

Heat pressrvation period | s | 25 | 25 | 25 | 25 |

Ice water temperature | °C | 1 | 1 | 1 | 1 |

Ice water consumption | multiple | 3 | 3 | 3 | 3 |

Cooling water consumption | multiple | 2 | 2 | 2 | 2 |

Connector size | mm | 32 | 38 | 51 | 51 |

Energy consumption | kw | 3 | 3 | 6 | 10 |

Outline dimensions | mm | 1500*1500*1800 | 1800*2000*1800 | 2200*2000*2000 | 2600*2000*2200 |

Spray drying is a wide applied process in liquid process shaping and drying industry.

Particularly suitable for producing powder, granule or block solid product from solution, emulsion, suspending liquid and pumped paste liquid.

Features of egg liquid drying machine:

1.In hot air stream, 95% to 98% of moisture can be evaporated immediately.

2.Quick drying speed:the surface area of material liquid through atomizing is increased greatly.

3. Product has good uniformity, fluidity, solubility, high pure, and quality.

4.For liquid containing 0~60% of damp(special may be 90%), it can be dried to powder through drying one time.

5.After dried, not necessary to crush, sieve therefore reducing productive procedure .

6.For the size, bulk density and moisture of product can be adjusted within certain scope through exchanging operation condition.

7.large flexibility of operation

8.no high requirement for factory buildings

Related Products

-

![Manufacture Quail /Egg/Duck Yolk Customized Divider Liquid Breaker Egg White Separator Machine]()

Manufacture Quail /Egg/Duck Yolk Customized Divider Liquid Breaker Egg White Separator Machine

-

![Factory Price Small Milk Beer Juice Plate Pasteurizer Batch Pasteurization Machine Flash Tube Egg Pasteurizer]()

Factory Price Small Milk Beer Juice Plate Pasteurizer Batch Pasteurization Machine Flash Tube Egg Pasteurizer

-

![LPG Spray Dryer Price Small Coffee Milk Egg Powder Machine Heating Atomizer Mini Centrifugal Spray Drying Machines for Soybean Protein Extraction]()

LPG Spray Dryer Price Small Coffee Milk Egg Powder Machine Heating Atomizer Mini Centrifugal Spray Drying Machines for Soybean Protein Extraction

-

![Commercial Usage Egg Peeling Machine Quail Egg Peeler Machine]()

Commercial Usage Egg Peeling Machine Quail Egg Peeler Machine