Manufactory and Trading Combo Automatical Milk Egg Liquid Pasteurizer

Package size per unit product 2000.00cm * 1500.00cm * 2000.00cm Gross weight per unit product 500.000kg Manufactory and

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | YGT-EGS |

| Process | Pasteurizer |

| Power Source | Electric |

| Certification | CE, ISO9001 |

| Automatic Grade | Automatic |

| Application | Milk, Yogurt, Egg Liquid |

| Customized | Customized |

| Transport Package | Pallet |

| Specification | 3000x1500x2000 |

| Trademark | YGT |

| Origin | China |

| HS Code | 84198990 |

| Production Capacity | 100set/Year |

Packaging & Delivery

Package size per unit product 2000.00cm * 1500.00cm * 2000.00cm Gross weight per unit product 500.000kgProduct Description

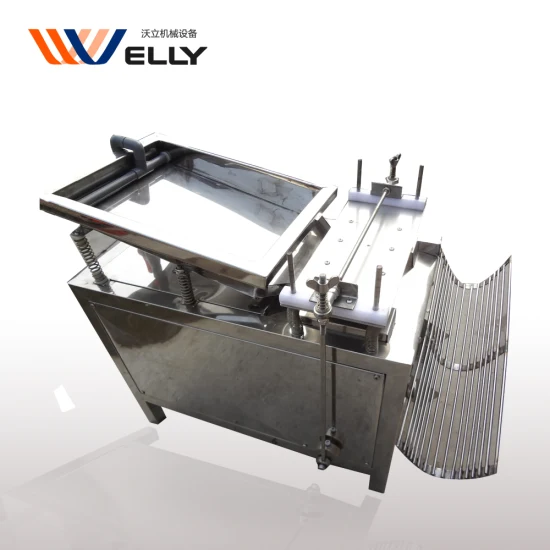

Manufactory and Trading Combo Automatical Milk Egg Liquid PasteurizerPlate Type Pasteurizer Machine

Introduction:

Milk pasteurization machine is a set of sterilization, cooling in one equipment, the machine is mainly used for pasteurization and cooling of fresh milk products. The working principle of pasteurization machine for milk is to take advantage of the heat-resistant characteristics of pathogens, treat them with appropriate temperature and holding time, and kill them all. After pasteurization, the nutrition of milk is effectively retained, and the milk is more healthy and tastes more pure.

Feature and Advantage

-High thermal effciency, 90% of the heat energy can be recycled after material heating.

-It is highly automatic degree. It can realize automatic control and record from CIP system cleaning to plate sterilizing and then to material sterilizing.

-Accurate and reliable sterilization temperature control. System affecting sterilizing temperature, steam pressure, flow and material flow are all controlled automatically.

-System with strong security. The parts all adopt reliable products with high performance, which value human and equipment's safety best. Steam, hot water and material all have pressure protection and alarm system.

-It is high reliability system. Main parts like material pump, steam valve, hot water pump, valves, electric elements adopt world famous brands.

-Direct heating ensures accurate and even temperature control, rapid heating and cooling, and can effectively shorten the production time.

Production process

4ºC→65ºC(Homogeneous)→85ºC (15s)→4ºC

Flow chart:

Milk

↓

Hot water→Plate heat exchanger 1

↓

Pasteurizer holding time (5s/15s/30s)

↓

Plate heat exchanger 2 (Heat recycle)

↓

Cooling water→Plate heat exchanger 3

↓

Filling or storage

Technical Data

| Process | 5ºC→65ºC sterilizing 15s holding→8ºC | ||

| BR 0.1C-B-1MJ | 1000l/h | 1.6x1.4x1.8m | 470kgs |

| BR 0.1C-B-2MJ | 2000l/h | 1.6x1.4x1.8m | 470kgs |

| BR 0.1C-B-3MJ | 3000l/h | 2.0x1.8x2.0m | 530kgs |

| BR 0.1C-B-5MJ | 5000l/h | 2.0x1.8x2.0m | 580kgs |

Plate Pasteurizer Picture:

Automatical milk Egg Liquid Pasteurizer

Related Products

-

![Large Capacity Industrial Cake Production Line Mousse Cake Making Machine Used Egg Breaker]()

Large Capacity Industrial Cake Production Line Mousse Cake Making Machine Used Egg Breaker

-

![Bulk Weighing Small Snack Sandwich Cookies Chocolate Hazelnut Flavor Sandwich Biscuit]()

Bulk Weighing Small Snack Sandwich Cookies Chocolate Hazelnut Flavor Sandwich Biscuit

-

![Egg Yolk Processing Machine/ Quail Egg Yolk White Separator Machine]()

Egg Yolk Processing Machine/ Quail Egg Yolk White Separator Machine

-

![Factory Supply Quail Egg Peeling Machine Quail Egg Peeler Quail Egg Shelling Machine]()

Factory Supply Quail Egg Peeling Machine Quail Egg Peeler Quail Egg Shelling Machine