Small Protein Powder Liquid Glucose Juice Coffee Centrifugal Drying Egg Milk Powder Making Machine Spray Dryer Machine

Descriptions The centrifugal spray dryer is the widely used technology in the liquid shaping technology and drying indus

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | GLP25 |

| Heat Source | Electricity, Steam, Coal Gas, Natural Gas, Fuel |

| Type | Centrifugal Spray |

| Functions | Spray Drying |

| Applicaitons | Tea, Milk, Egg, Flavors and Other Powders |

| Efficiency | Over Than 95% |

| Max. Water Evaporation | 5-2000kg/H |

| Used for | Emulsion, Suspending Liquid, Wet Granules and etc |

| Control System | PLC Control |

| Voltage | 380V/50Hz |

| Features | Fast, Easy Operation, Low Cost |

| Delivery | Within 1.5 Months |

| Exported to | America, Russia, Dominica, Mexico, Venezuela |

| Inlet Temp. | 140-350 Auto-Control |

| Outlet Temp. | 80-90 |

| Spraying Nozzle | Mechanical Transmission |

| After Sale Service | Online or Technicians Oversea Training Available |

| Shipping Port | Shanghai |

| Transport Package | Wooden Box |

| Specification | Stainless steel |

| Trademark | Snynxn |

| Origin | Jiangsu |

| HS Code | 8419399090 |

| Production Capacity | 10set/Month |

Product Description

Descriptions

The centrifugal spray dryer is the widely used technology in the liquid shaping technology and drying industry.Lt is most suitable for producing powder, particle solid products from materials of solution, emulsion, solidus and culpable paste states, Therefore, when the particle size of the distribution final products, the residual water contents, the stocking density and the particle shape meet the precision standards, the centrifugal spray dryer is one of the most desired technologies.

Technical parameters

Model | 5 | 25 | 50 | 100 | 150 | 200-10000 |

| ºC Inlet temperature | 140-350 140-350 automatic control | |||||

| ºC outlet temperature | ~80-90 | |||||

| kg/h Maximum moisture evaporation | 5 | 25 | 50 | 100 | 150 | 200-10000 |

| Centrifugal spray head drive | Compressed air drive | mechanical drive | ||||

| (r.p.m) speed | 25000 | 18000 | 18000 | 18000 | 15000 | 8000-15000 |

| (mm) Spray disc diameter | 50 | 100 | 120 | 140 | 150 | 180-340 |

heat source | electric | + Electricity + steam | +, Electricity + steam, fuel, gas | Resolved by the user | ||

| kW Maximum power of electric heating | 9 | 36 | 63 | 81 | 99 | |

| L×W×H(m) Outline dimension | 1.8×0.93×2.2 | 3×2.7×4.26 | 3.7×3.2×5.1 | 4.6×4.2×6 | 5.5×4.5×7 | Determined according to specific circumstances |

| % Dry powder recovery | ≥95 | ≥95 | ≥95 | ≥95 | ≥95 | ≥95 |

Note: evaporation of water is related to the characteristics of the material and the temperature of the inlet and outlet

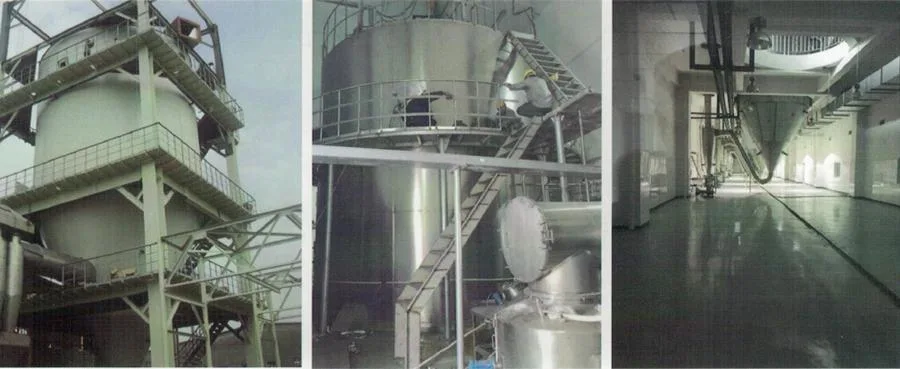

Principle of work

After filtering and heating, the air enters air distributor at the top of the dryer. The hot air enters the e drying chamber in the spiral form uniformly. By passing through the high-speed centrifugal atomizer at the top of the tower, the material liquid will be rotated and sprayed into extremely fine mist liquid beads, Through the very short time of contacting with hot air, the materials can be dried into the finished products. The finished products will be discharged continuously from the bottom of the drying tower and from the cyclone separator.The waste gas will be discharged by blower.

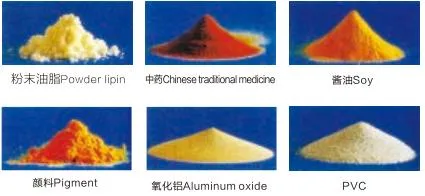

Dried samples

Foodstuff: Amino acid,Vitamin,flavoring,protein,dried milk,pig blood powder,soy powder,coffee,tea powder,Glucose,potassium,sorbe,pectin, essence,vegetable juice,yeast,starch etc.

Ceramics: Alumina,Marconi,magnesium oxide,titanium oxide,magnesium titanate,pottery clay,china clay,all kinds of magnetic porcelain and metal-oxides etc.

Chemical products: Dispersed dyestuff,active dyestuff,organic catalyst white carbon black,detergent powder,zinc sulfate,sodium metasilicat,potassium fluoride,calcium carbonate,tribasic potassium phosphate,inorganic catalyst and all kinds of waste liquid etc.

Flow diagram

Features and Outlines

Features

1 .High speed of drying. After the spraying of the material liquid, the surface area of the material will be increased greatly. In the hot-air flow,95%-98% of water can be evaporated at the moment.The time of completing the drying needs only several seconds.lt is especially suitable for drying the heat sensitive materials.

2. Ats final products own the good uniformity, mobility, and dissolving capacity. And the final products are high in purity and good in quality,

3. The production procedure is simple and the operational control easy. The liquid with the moisture contents 40-60% (for special materials, The contents may reach 90%.)can be dried into powder or particle products at a time. After the drying, there is no need tor smashing and sorting, so as to reduce the operation procedures in the production and Chance the product purity .The product particle diam enters, looseness and water contents can be adjusted through changing the operation condition in a certain scope, It is very convenient to carry out the control and management.

Outlines

1. Atomization: Atomizing system must ensure a uniform distribution of the fog drops, which is crucial to ensure a good qualified rate of products.

2. Contact of hot airflow and fog drops: When enough hot air enters into drying tower, the direction and angle of hot air flaw have to be considered, no matter co-current flow, adverse current or mixed flow, must ensure the sufficient heat exchange, it is crucial.

3. The angle design of pipelines and cone: Lt is very important to select the suitable angle, here we would like to share our experience and data from production of thousands of this equipment.

Technical parameters

Model | 5 | 25 | 50 | 100 | 150 | 200-10000 |

| ºC Inlet temperature | 140-350 140-350 automatic control | |||||

| ºC outlet temperature | ~80-90 | |||||

| kg/h Maximum moisture evaporation | 5 | 25 | 50 | 100 | 150 | 200-10000 |

| Centrifugal spray head drive | Compressed air drive | mechanical drive | ||||

| (r.p.m) speed | 25000 | 18000 | 18000 | 18000 | 15000 | 8000-15000 |

| (mm) Spray disc diameter | 50 | 100 | 120 | 140 | 150 | 180-340 |

heat source | electric | + Electricity + steam | +, Electricity + steam, fuel, gas | Resolved by the user | ||

| kW Maximum power of electric heating | 9 | 36 | 63 | 81 | 99 | |

| L×W×H(m) Outline dimension | 1.8×0.93×2.2 | 3×2.7×4.26 | 3.7×3.2×5.1 | 4.6×4.2×6 | 5.5×4.5×7 | Determined according to specific circumstances |

| % Dry powder recovery | ≥95 | ≥95 | ≥95 | ≥95 | ≥95 | ≥95 |

Note: evaporation of water is related to the characteristics of the material and the temperature of the inlet and outlet

Company profile

Division I professional production of various kinds of pharmaceutical machinery and drying equipment, our products sell well in over 20 provinces and cities, and exported to America, Mexico, Spain, Singapore, Russia, belarus, Egypt, South Korea, Malaysia, the Philippines, the united Arab emirates, Thailand, Vietnam, Pakistan, India, Iran, South Africa, Algeria, Syria, Mongolia, Bangladesh and other countries. The company is constantly updating and developing pharmaceutical machinery, chemical equipment, drying equipment, mixing equipment, granulator, coater and sewage treatment equipment and other products. With strict testing means and a complete set of scientific management procedures, and through the ISO9001 international quality system certification, product quality has reached the advanced level at home and abroad, pharmaceutical machinery products in line with "GMP standard". Our company tenet: product quality to win with excellence, sales and service to honesty, the contract to honor the letter.

Corporate core values

Pay attention to technology creation, improve quality, quality and service

Corporate mission

Let customers create more value, contribute more wealth to the society, and establish a respected brand for the country

Talent concept

People-oriented, pay attention to talent, to establish the cradle of talent to research core technology

Respect employees, identify with employees, give employees a safe harbor and a stage to show their talent

Business philosophy

Win-win cooperation

Related Products

-

![White Egg Separator Egg Separator Nose Tricetops Egg Separator Egg Separator Chicken Machine Egg Separator Broken and Separator Eggs Egg Yolk White Separator]()

White Egg Separator Egg Separator Nose Tricetops Egg Separator Egg Separator Chicken Machine Egg Separator Broken and Separator Eggs Egg Yolk White Separator

-

![Top Quality Centrifugal Type Egg Breaker]()

Top Quality Centrifugal Type Egg Breaker

-

![Egg Topper and Cracker for Perfect Soft Boiled Eggs]()

Egg Topper and Cracker for Perfect Soft Boiled Eggs

-

![Boiled Quail Egg Peeling Shelling Machine for Sales]()

Boiled Quail Egg Peeling Shelling Machine for Sales